Like you, we don’t want to see anything go to waste. (I mean, does anyone?)

It’s why we make stuff to last and use everything from leftover coffee sacks to used paragliders in our products. “Repurposed for a Purpose” is the norm around here — and you can see it all around our 90+% repurposed headquarters here in Portland.

But upcycling is about much more than feeling good about giving materials a second life. It often means we can reduce our use of petrochemicals and virgin materials. And diverting waste from landfills makes a significant impact, too. Because all that garbage generates methane, a greenhouse gas that is 28 to 36 times more potent than carbon dioxide at trapping heat in the atmosphere,” according to the U.S. Environmental Protection Agency.

(Did you know landfills are the third largest source of human-related methane emissions? We didn’t either until recently.)

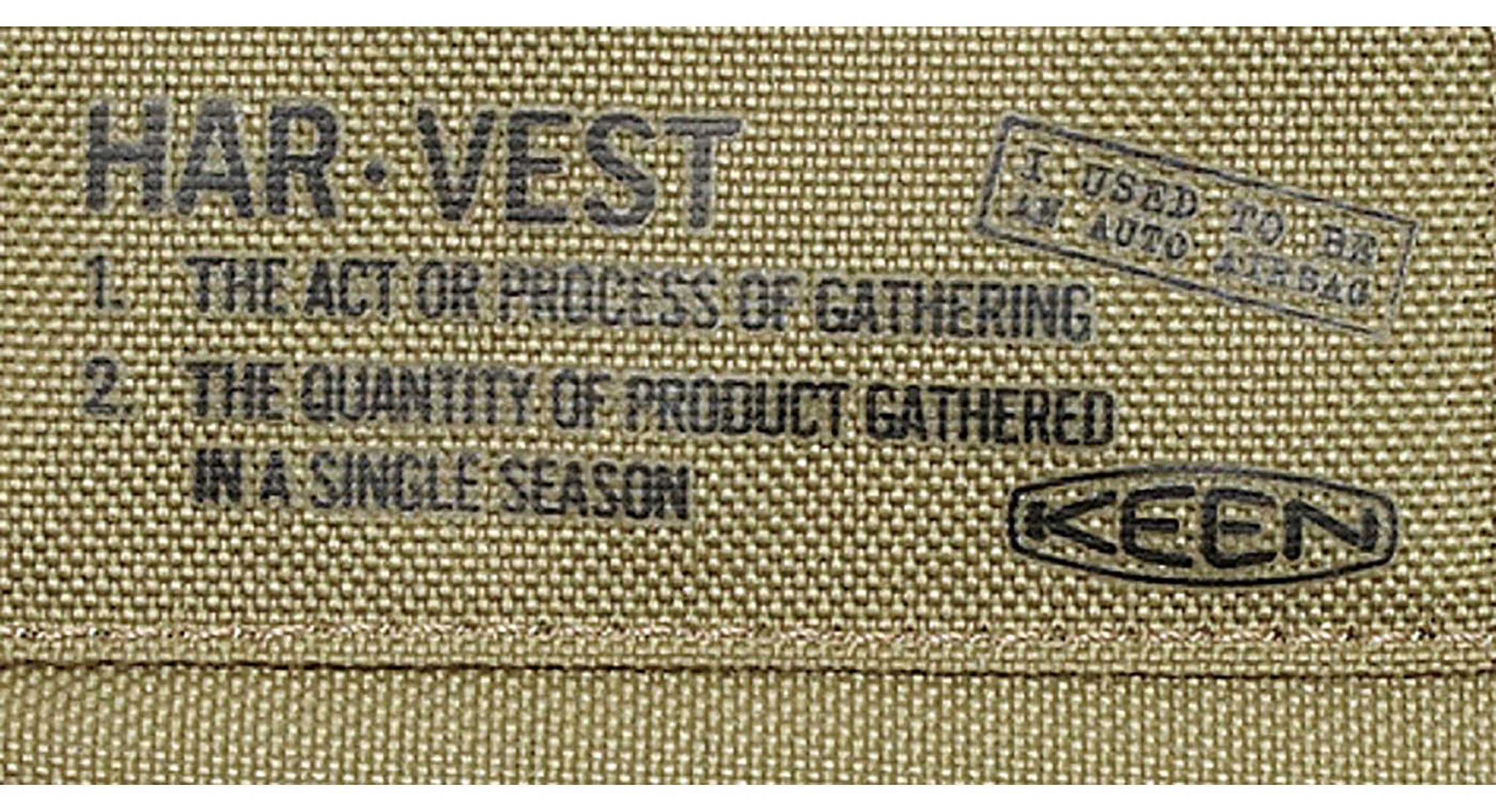

So, being conscientious shoemakers isn’t just about what we put in our shoes, it’s also about what we keep out of landfills. We call it the Harvest collection, and it’s all part of our Detox The Planet initiative.

Plant-Based Soles = Lighter Footprint

We first launched Harvest products 15 years ago using industrial waste from the rice industry. Since then, we’ve taken leftover automobile airbags and turned them into backpacks, totes, messenger bags, and wallets. We’ve repurposed denim waste by upcycling it into shoes (I have a pair!). We made twice-upcycled bags from sacks that held coffee beans, and we created our most recycled flip-flop ever.

"This plant-based goodness replaces 51% of the petrochemicals in the outsole and 35% in the midsole."

Our latest example of putting waste into our shoes: our first-ever plant-based PU sole. You’ll find it in our women’s Elsa V and men’s Eldon natural cotton canvas sneakers. We took industrial agricultural waste — leftover bits like husks, leaves, and stems — and put it in the sole. This plant-based goodness replaces 51% of the petrochemicals in the outsole and 35% in the midsole. And our plant-based insole, launched a few years ago, features 70% renewable bio content. That adds up to a lot of good stuff underfoot.

Industrial waste is a big problem. In the U.S., 97% of all solid waste is generated by agricultural and industrial processes. And, according to the Post Carbon Institute, only about 2 percent of it is currently being recycled. Replacing the petrochemical polyol base in our polyurethane (PU) soles with a bio-based polyol made from industrial agricultural waste is an exciting step forward. Our new plant-based PU sole has the same feel, performance, and durability — just with a lighter footprint.

How much waste is upcycled per shoe?

We think you should know exactly how much waste goes into each shoe, and we want to help other shoemakers “harvest” industrial waste, too. So, as part of our Detox the Planet Initiative, we’re building the KEEN Harvest Certified Program, providing transparency into how much industrial waste is upcycled into shoes. Not just ours … but everyone’s.

Launching in early 2022, the KEEN Harvest Certification Program will feature three levels of certification: Gold (greater than 50% upcycled materials); Silver (greater than 25%); and Bronze (greater than 10%). That way people can see exactly how much waste is upcycled into the shoes they buy. The first shoe with this certification, the Howser Harvest, is Gold-certified using upcycled car seat leather in 80% of the upper.

"We hope to see other brands adopt and even improve on what we’re doing and, in turn, share their learnings with others. We need to work collectively if we want to create real change."

“We’re certifying Harvest products to both provide transparency to fans and to demystify and encourage other brands to help attack the industrial waste problem,” says Erik Burbank, our VP of doing good. “We’re continuing our research on new Harvest materials, refining the overall model, and plan to open-source the program in early 2022. This isn’t about creating a competitive advantage for KEEN. We hope to see other brands adopt and even improve on what we’re doing and, in turn, share their learnings with others. We need to work collectively if we want to create real change.”

It’s not quite circular, but it’s a start. By rethinking waste, and using more bio-based and recycled materials in our products, we are moving further away from a linear mentality. We want to set things on a better trajectory by creating shoes made with waste. Not waste destined for landfills.

“Less waste in landfills, less virgin materials sourced, less greenhouse gasses emitted — it’s a trifecta of benefits for the planet,” Erik says. “And we hope it only gets bigger.”

Our Detox the Planet Initiative was established in 2012 to proactively identify and remove harmful chemicals in our supply chain and replace them with safe and effective alternatives. Our manufacturing process is PFC-free; we use pesticide-free, natural odor control; and we only partner with environmentally preferred Leather Working Group certified tanneries. And we have a lot more work to do...